Custom Services

Sunzza offers flexible custom services to bring your packaging ideas to life — from size and shape to logo and finish. We tailor every detail to match your brand and product needs.

From local chains to international retailers, hundreds of food service brands rely on us for high-performance, beautifully branded sushi packaging. Our expert team delivers tailored packaging solutions that reflect your brand identity, enhance product presentation, and meet strict food safety standards.

Established in 1996, we bring decades of experience serving clients across 100+ industries. Our deep understanding of diverse market needs enables us to offer precise, reliable, and proven customized solutions.

With a skilled technical team and advanced production equipment, we ensure each customized product meets the highest standards in quality, performance, and regulatory compliance.

Every project is different—we understand that. That’s why we provide fully flexible customization options in design, material, structure, and function to match your exact requirements.

We implement advanced inspection systems and dedicated quality processes for each stage of production, ensuring consistency, safety, and customer satisfaction in every order.

Thanks to our large-scale manufacturing and efficient sourcing, we offer competitive pricing while maintaining premium quality—helping you reduce costs without compromise.

From initial consultation to sample production and delivery, we respond quickly and communicate proactively, ensuring your custom orders are completed on time and with care.

Whether you're testing new packaging designs or responding to seasonal product demands, we support low minimum order quantities to give you the flexibility to try without overstocking. Small-batch orders allow you to validate market feedback quickly and cost-effectively, reducing risks and improving response speed—making it the ideal choice for brand trial runs and rapid iterations.

For medium and large-scale orders, our robust in-house production system and global supply chain ensure reliable delivery and competitive pricing. Whether you require ongoing procurement or large-volume shipments, we offer transparent cost calculations and tailored quotes to support efficient brand expansion and confident market deployment. Contact our team for your personalized solution!

Step 01

Customers provide design requirements, drawings and samples.

Step 02

Estimate product prices based on customer requirements, Customers start drawing after confirming the quotation (the sample fee and mold fee need to be paid in advance).

Step 03

YADA draws and optimizes the drawing according to the customer's requirement or sample, and presents it to the customer for confirmation in 2D or 3D drawing.

Step 04

After the customer confirms the drawing, we can provide an accurate quotation.

Step 05

After price confirmation, we will arrange the production of molds and samples.

Step 06

After the mold is completed, we will complete the production of the first sample within 3-20 days and send it to the customer for inspection.

Step 07

Upon receiving the sample, customers will inspect and verify the first sample, and provide feedback on the inspection results to us.

Step 08

Once the customer confirms that the sample is qualified, we will start mass production.

Step 09

After production is completed, we will test product requirements to ensure product compliance.

Step 10

When the inspection results meet the requirements and the customer confirms that the goods can be shipped, we will arrange shipping.

We offer a wide range of food-grade materials tailored to your needs, including biodegradable plastics, recyclable PET, kraft paper, and coated cardboard. All materials are certified for direct food contact and selected to balance durability, presentation, and sustainability. We can also advise on the best material based on your packaging design and transportation requirements.

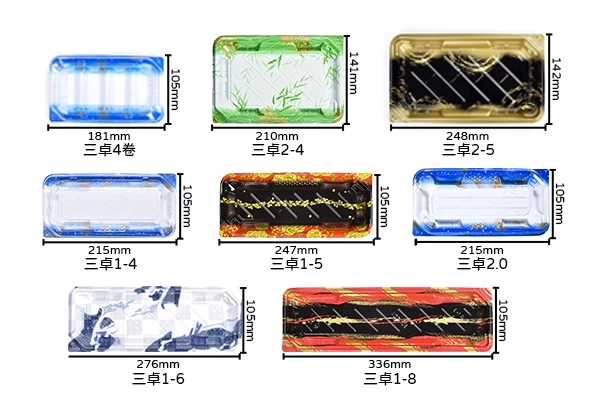

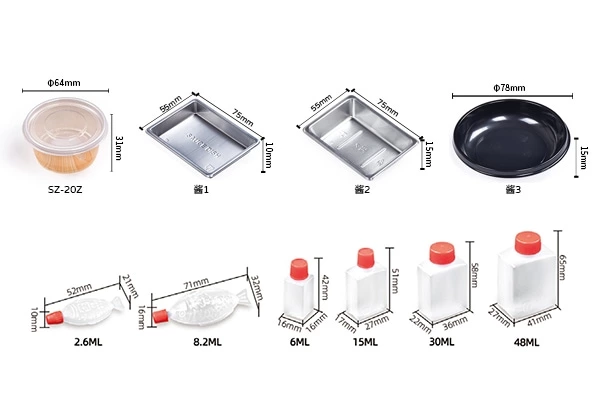

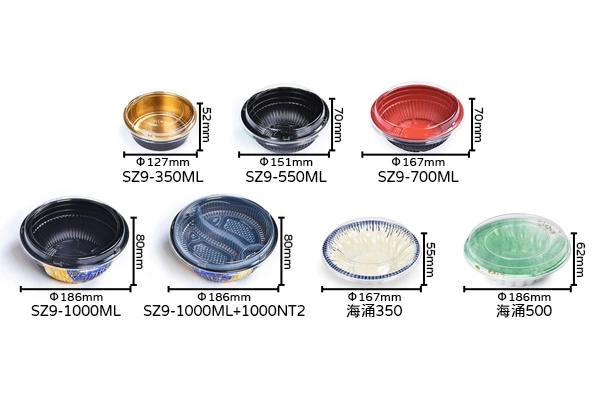

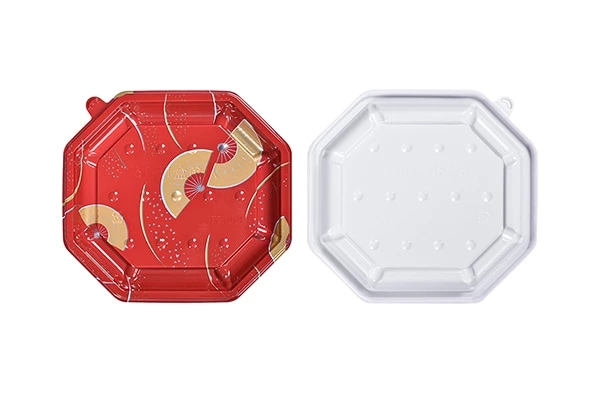

Yes, our packaging solutions are fully customizable. Whether you need a compact box for a single sushi roll or a multi-compartment tray for full sets, we can design and produce packaging that fits your exact specifications. Custom shapes, internal dividers, and lids can also be developed according to your serving style.

Absolutely. We offer multiple printing options including offset, flexographic, and digital printing, depending on your quantity and budget. You can add your logo, brand colors, product names, and even QR codes. Custom branding helps enhance visibility and makes your sushi packaging stand out in retail and delivery settings.

Yes, all of our containers are made from certified food-grade materials and comply with international safety standards such as FDA, SGS, or EU regulations. We take food safety seriously and ensure that the inks, adhesives, and base materials used in your packaging are safe, odorless, and suitable for both hot and cold items.

The minimum order quantity (MOQ) generally starts from 500 to 1000 units, depending on the complexity of your design, printing method, and material selection. For simple designs, we may be able to offer a lower MOQ. Bulk pricing discounts are available for larger quantities.

Lead time typically ranges from 15 to 30 days after design confirmation. This includes the prototyping, material sourcing, and mass production phases. Delivery time will depend on your location and shipping method. For urgent orders, expedited production services are also available upon request.

Yes. Our packaging is specifically designed to preserve the texture, temperature, and appearance of sushi. Features such as tight-fitting lids, anti-leak compartments, and ventilation holes help maintain freshness during delivery or takeaway. We also offer cold pack–compatible packaging if needed.

We provide several eco-friendly packaging options including compostable PLA plastic, recyclable paperboard, and biodegradable materials. These sustainable choices help reduce environmental impact and can also align with your brand's green values. We can even print eco-labels on your packaging if needed.

Yes, we highly recommend ordering samples first to evaluate size, material, and overall appearance. Sample orders typically take 5–7 days to produce. This ensures you’re fully satisfied with the design and quality before committing to larger production runs.

Yes, we offer specialized materials and structures that are heat-resistant and moisture-proof. These containers are ideal for warm sushi variants like grilled eel rolls or tempura. Ventilation features and heat-sealed lids help maintain the right texture without steaming the contents.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.more details